Wazowski upgrade

|

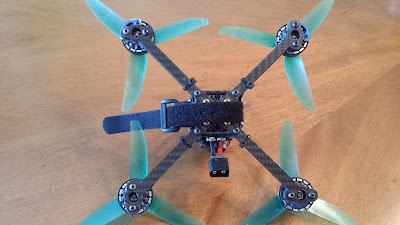

| With 2205 motors, this weighs 232.8 grams |

Wazowski was my first attempt at building ultra light weight quadcopter for racing purposes. This was built on summer 2017 and since then, it has been going though constant upgrades to achieve better flight experience.

Goals for this upgrade was to:

- reduce weight even further

- strengthen the tower structure

- have onboard DVR

- have clover leaf antenna instead of dipole antenna (allows racing with multiple pilots at the same time)

Parts used for this upgrade:

On board DVR

|

HMDVR-S

|

Top plate

|

QAV-ULX carbon fiber top plate

|

Standoffs

|

Anti-vibration damper with fixed screws

|

VTX antenna

|

UXII Stubby LHCP UFL 5.8GHz 1.6dBi

|

Propeller

|

HQ 5*4.3*3

|

| Personal rate settings from Betaflight (enlarge image size to see details) |

| Left: traditional rotation, Right: reversed rotation |

Picture above depicts quadcopters in forward flight. Blue arrows mean the quadcopters are moving forward, white arrows show the rotation of the propellers, and red dots show the center of thrust of each propeller.

I swapped all 4 motors and propellers to have propellers spinning in opposite direction compared to the traditional rotation. There are aerodynamic benefits to this setup for racing and this video explains the theory in detail. As the quadcoter moves forward, the spinning propeller's advancing blade produces more thrust than the retrieving blade. This shifts the center of thrust towards the advancing blade. Regardless of the prop rotation direction, rear propellers work less efficiently than the front propellers in forward flight because they have to deal with turbulent air created by the propellers spinning at front. Center of thrust at the outer position compensates this inefficiency due to principle of moment. It is also said that in reversed prop rotation setup, rear motors can work more efficiently under fast yaw movements.

Other advantages are since the propellers are now spinning outward from the camera lens, I don't have to clean the lens as often since it is free from debris coming from propellers. Also, since the propellers are now pushing "away" whatever objects coming towards at the center of the quad when forward flying, it is less likely to get tangled up on things like tree branches.

Also, new propellers (HQ 5*4.3*3) are installed. I found them durable and efficient, I can see why many fpv racing pilots say this is one of the best props in the market.

|

| Bottom view |

|

| What have I done... |

| Close up views of rear(left) and front (right) motors |

|

| HMDVR-S onboard DVR and LHCP antenna installed |

Onboard DVR is added on the back of the quad. This only weighs approx 4 grams total with the micro sd card and heat shrink cover. Advantage of having an onboard DVR is that it can record video footage without capturing all the signal glitches seen on the goggle.

Also, RFX185 frame's top plate is replaced with QAV-ULX's top plate which has more material around the M3 holes to hold onto the screws.

|

| Flight controller is happy with rubber rings + 2 floors of vibration dampers |

|

| All up weight is 404.6 grams with 4cell 1500mah LiPo battery |

|

| Rear view |

I'm a broke college student so I try to upgrade as much as possible before moving on to building another completely new setup. Most of the upgrades are therefore hardware related modifications while I try not to replace all the expensive electronics. Some tinkering with the betaflight software are usually part of the upgrade as well. Wazowski has been going through upgrades for almost a year now and I think it is now reaching it's limit in terms of flight performance unless its flight controller and all 4 motors are replaced with better components. That would be a huge investment as those are usually some of the most expensive parts in a quadcopter. Anyways, I say Wazowski is still a solid race quad as all the upgrades and improvements done to it compensates for the old components it is using.

Upgrade summary:

- reversed propeller rotation

- replaced dipole antenna with clover leaf antenna

- remove excess weight from the motors

- replace top plate with beefier plate

- HQ 5*4.3*3 propellers

- replaced nylon standoffs with vibration damping standoffs

- added onboard DVR (HMDVR-S)

- newest Betaflight filmware at the moment (Betaflight 3.3.0)

- optimized transmitter joystick movement

- permanently turned on airmode, anti gravity, and dynamic filter features

- disabled arming angle

- adjusted rates for more race compatible setup

- added prearm feature for extra safety

- etc... (miscellaneous small improvements)

Improvements for future iterations:

- top mounted battery placement

- better flight controller

- better motors

- 6cell LiPo

- I might as well just build another drone