Radii - beetle weight drum spinner battlebot (February 2017)

|

| This won 3rd place in Motorama 2017 with 5 wins and 2 losses |

Radii is the first battlebot I built after joining Robojackets Battlebot in Fall 2016.

The goal of this project was to...

- make a working drum spinner robot

- learn CAD and how to machine (waterjet, mill, lathe, etc)

- compete in Motorama 2017

|

| Looks like a fine toaster |

The cad was done using Autodesk Inventor. Efforts spent in ME 1770 (Georgia tech CAD course) finally got put into a good use.

|

| CAD internal view |

|

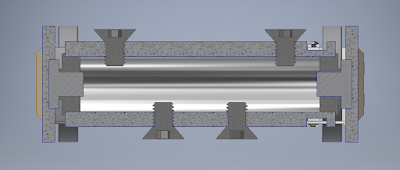

| half section view of the drum weapon |

The spinning drum weapon is driven by belt attached to motor. Groove made at the left side of the drum is where the flat belt sits, connected to the pulley on the motor.

Drive motors are pushed toward the back to leave space at the front for the weapon motor and motor controllers. 3 cell lithium polymer battery is placed at the back along with the receiver and the switch.

Most of the chassis and the drum (weapon) is made out of 6061 aluminum since they are cheap and easy to machine. The bolts screwed on the weapon are black-oxide alloy steel since those would be the part where it will actually contact the opponent battlebots. Covering the back and the side plates are HDPE plastics for extra protections.

|

| Fabricated. And somewhat battle damaged - rear view |

I forgot to take a photo right after it was fully made. Trust me, Radii was more shiny than in the photo above.

All the aluminum plates including top and bottom are cut into shape using waterjet. Motor mounts inside and the side plates are then CNC milled to carve out pockets for extra space for the motors and weight savings to meet 3lb restriction. The drum weapon and shafts that holds the drum are made using lathe and then CNC milled for inserting screws. All processes are followed by exciting tapping procedures. I probably broke around two 4-40 taps along the way.

Electronics used for the build were

| Drive Motors | 9.7:1 Metal Gearmotor 25Dx48L |

| Drive Motor Controllers | Scorpion Mini |

| Weapon Motor | Turnigy 2836 Brushless 450-Size Heli Motor 3200kv |

| Weapon Motor Controllers | HobbyKing 40A ESC w/UBEC 4A |

| Receiver | Hobby King 2.4Ghz Receiver 6Ch V2 |

| Remote Control | Hobby King 2.4Ghz 6Ch Tx and Rx V2 |

| Battery | Turnigy nano-tech 1000mAh 3S 45~90C Lipo Pack |

|

| Next to other fabricated 3lb battlebots from Robojackets |

|

| Battle damaged after getting hit by Project Darkness. Weapon teeth and the aluminum drum deformed heavily. |

|

| Robojacket Battlebot crews at Motorama 2017 I'm the 3rd from the left |

|

| Trophy (or an over-sized nut) proudly displaced in student competition center |

Not bad for my first competition. It fought total of 7 fights, winning 5 and losing 2. I was lucky not going against horizontal spinner types in the first 5 fights. Radii was relatively well designed to take vertical loads but was critically weak against horizontal impacts as it lacked enough materials that prevent the robot from shearing. As a result, Radii performed fairly well against battlebots with vertical weapons or wedges but met its demise after it fought against horizontal weapon types: silent spring and dinner time (extremely well designed & made battlebots in my opinion).

It was my first battlebots so there were many flaws to the design. First of all, Radii was extremely difficult to drive. The wheels were too far away from center of mass so the two side skids next to the drum were primarily touching the floor instead of the wheels at the back. Unless all 4 points are aligned flat (2 skids, 2 wheels), Radii would just spinning in one direction. The belt that was used tend to stretch easily and made quite a lot of slips while spinning the weapon. Layers of electrical tapes were used to enlarge the diameter of the pulley to adjust belt tension. Also, there was nothing at the front which prevents the side plates from shearing. Few 4-40 screws going through the 1/16 thick aluminum plates at the top and bottom was the only thing that was holding the side plates inward together and this was a very weak setup especially going against horizontal weapon types. One single good hit from both silent spring and dinner time was enough to bend the side plates completely and have weapon popped out from the robot.

For future iterations, improvements that can be put into design are...

- belt tension adjusting mechanism

- kevlar/ carbon fiber/ fiberglass composites for armors

- single steel bar drum teeth (instead deforming the relatively thin bolts)

- wedge at front

- smaller drum length to allow more side armors

- more weight toward the back (wheels closer to center of gravity)

- shaft or aluminum plate to keep side plates from shearing at the front

Many thanks to Thatcher for being a great mentor for this project, Eunchang for being a helpful team member from CAD to all the way to fabrication, Paul for helping out in machining, and Robojackets for providing the opportunity to make a battlebot and compete. Future iterations of this robot follows soon.

No comments:

Post a Comment